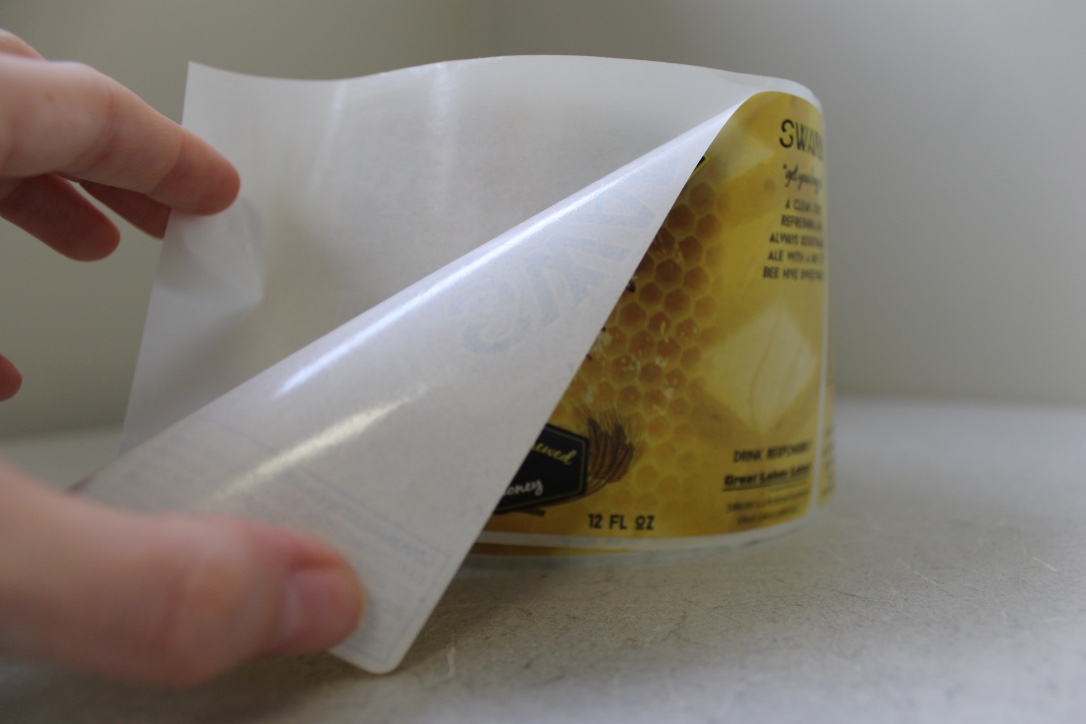

Pressure sensitive adhesives form a bond to label stocks at any time, is permanently tacky, plus they are capable of bonding to almost any surface. No activation by water, solvent or heat is necessary. Your labeling needs have an impact the adhesive you use.

Acrylic Solutions

Solvent-based acrylic formulations get overshadowed by water-based and hot-melt systems. This is because of economic as well as ecological reasons. Solvent recovery and/or incineration meet clean air legislation requirements. Such equipment is expensive and is only justified for large output operations. Because of this, acrylic solution adhesives don’t have much use today. However, they do get used for specialty applications such as glass clear “no-label” look, PET labels or PVC labels where optimum water resistance is needed.

Rubber/Resin Solutions

These infrequently used solutions end up coated with a solvent. One exception is for high performance “peelable” labels and uncommon labeling needs for items such as oil cans.

Pressure Sensitive Hot-Melts

Hot-melt pressure-sensitive adhesives are a fast-growing sector because of their durability. They provide strong tack and some recipes have excellent performance in cold and wet conditions, particularly for labeling plastics. Hot-melts are easy to coat on compact equipment and are also the preferred choice for most in-house converters and printers.

Acrylic Dispersions

Water-based acrylic dispersions (emulsions) is now the dominant technology for the label stock producer and can also offer a practical option for in-house coaters.

Radcure

Adhesives can be cross-lined (cured) by electron beam or ultra-violet radiation. This enhances some characteristics such as a high-temperature performance of hot-melt adhesives.

Pressure-sensitive label adhesives can provide a permanent bond or can be removable, a wide range of options. Some substrates easily to stick to paper or board. However, pressure sensitive adhesives have the option for hardy formulations that stick to “difficult” surfaces such as textured plastic containers or wet bottles. The cohesive strength of pressure sensitive adhesives also allows labels to potentially disintegrate to discourage tampering.

Learn more about designing effective, professional grade labels. Download our Label Project Guide.

Connect with us on social media!