About Universal Labeling Systems

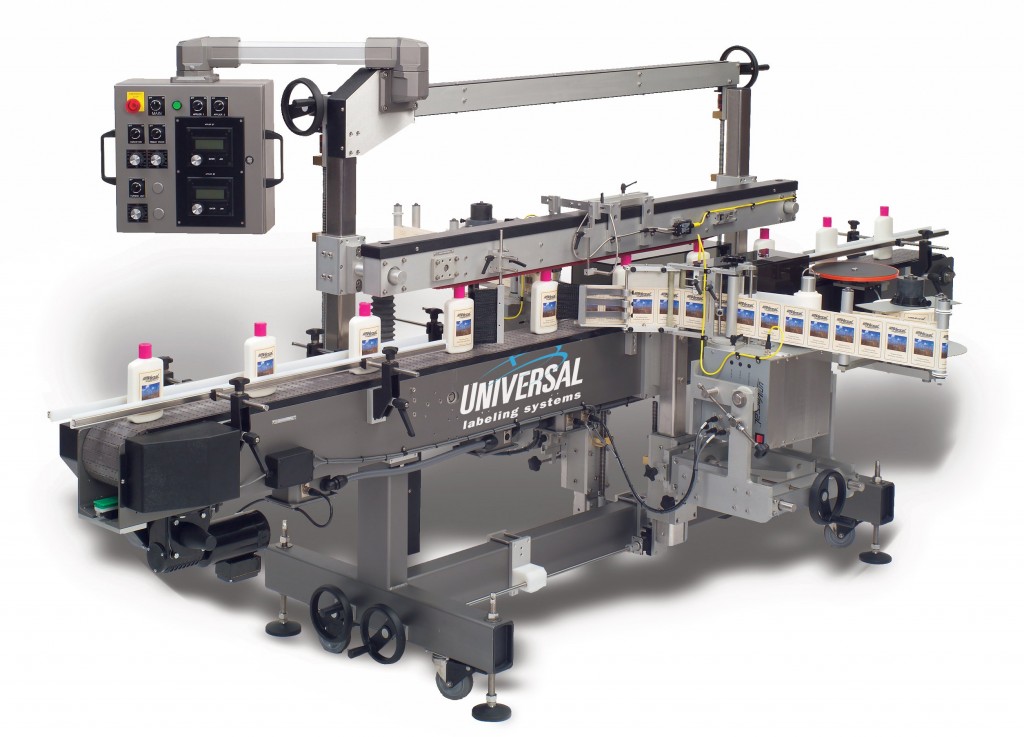

Universal Labeling Systems is a leading manufacturer of pressure-sensitive labeling machinery.

They are North America’s largest manufacturer of made-to-order, pressure-sensitive labeling equipment.

No other labeling machinery manufacturer can lay claim to as many uniquely designed systems as Universal. Whether it is an in-line, tabletop, or print & apply, Universal sets a lofty standard for quality and reliability.

See Universal in Action

Various Pressure Sensitive Labeling Machinery

Application types include wipe-on (merge) labeling for rounds and front and back applying for flats and ovals, and tamp, tamp-blow, or blow-on style applicators for flat-sided and oval products. Universal Labeling Systems is equipped with technologies including both stepper and servo-driven with 80% of all machines and product handling designed and built to a specific labeling application. Choose from accessories such as hot stamp imprinters, feeders and accumulation tables, and heavy-duty base stands.

Made to Order Labeling Systems with You in Mind

Based on your product and the labeling method you choose, Universal Labeling Systems has a labeling machine designed for you. Universal now offers over 20 different types of labelers, no job is too big or too small for Universal.

The Added Value

Take advantage of the benefits. We provide guaranteed support and service on all of our label applicators. Not sure which applicator is right for you? Great Lakes Label can find the best fit for your operation. We offer the most up-to-date line of products from leading applicator manufacturers.

Featured Universal Label Applicators

Featured Universal Label Applicators

The CP1000- Front & Back Packaging System

Features: The best multi-purpose labeling system just got better! Universal Labeling Systems announces major advancements in the labeling technology of their Contract Packager Series. The CP 1000 has a digital control package, and multi-level system adjustments not found in standard “front & back” labeling systems. The CP1000 can label fronts & backs of F style containers, apply and orient labels on one-gallon jugs, and apply multi-side labels to oval and square bottles, and all with limited changeover! All of this in one system…the CP1000 system.

The R320- Round Product Labeling System

Features: The R320 / R321 / R322 automatic round product labeling systems provide you with the ability to label cylindrical products at speeds from 20 to 300 products per minute. The R320 is the entry-level system for those getting started in automating their labeling process. The R321 goes a step further by providing increased speeds and product-to-label synchronization. The R321 automatic for rounds has options that include product encapsulation, product orientation, and the ability to be customized for conical-shaped products. And the R322 is the high-speed big brother in the automatic round product labeling series, featuring extra wide labeling abilities as well as an option for a vertical trunion(to learn more). The R320 / R321 / R322 automatic round product labeling systems are built with one thing in mind, you and your labeling needs.