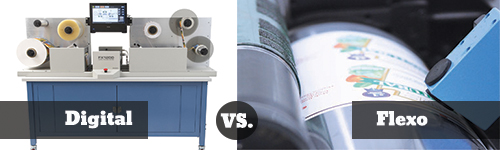

Digital Labels vs Flexographic Labels:

Understanding the best solution for your printing needs.

The growth of the custom label market spawns new technologies and a myriad of printing options. With the label being a crucial factor in the success or failure of your product, it is important to understand which labeling solution is the most appropriate for your needs. This is the battle of digital labels vs flexographic labels.

The Basics

Flexographic Printing uses flexible printing plates made of either rubber or plastic. Similar to a rubber stamp, the flexible plates have a slightly raised image. The inked plates rotate on a cylinder of a printing press. The image is then transferred onto material or label stock.

In contrast, Digital Printing transfers images or designs onto label stock using inkjet or laser printer technology.

Benefits of Flexo

One of the primary benefits of flexographic printing is that it can be used to print on a variety of different base materials (substrates) such as; plastic films, foils, textiles, fabrics, a variety of paper, parchment, and plastic containers.

With the use of HD Flexo plates, flexographic printing boasts excellent print quality, vibrant colors and print consistency.

Flexographic printing is cost-effective for multiple label runs and large run label projects.

Benefits of Digital

Because digital printing doesn’t require the use of plates, the turnaround time is often faster than that of flexographic printing. When it comes to altering the design of your label, digital printing offers more flexibility. This is because a plate does change with an image or design. Digital printing is also more affordable for short-run or lower quantity labels.

Drawbacks of Digital

Unlike flexographic printing, there is a limited selection of materials to print on. Since digital printing presses use heat in their printing process, materials must have a low sensitivity to heat for printing.

Use flexographic printing for large print jobs. In fact, a large job running on a digital printer is the least cost-effective solution.

Drawbacks of Flexo

The cost of flexographic printing plates, used to transfer images onto label stock or label material, is one drawback of flexographic printing. However, when printing a large number of labels, the plate cost is minor compared to the speed of the printing method and production cost savings. Digital printing is the better solution for short-run printing jobs because of the cost of printing plates.

The Takeaway

It is important to note that a specific solution depends on your needs and your goals for a specific job or project. In order to determine the right printing solution, talk to an experienced label expert, trained to meet your needs and requirements in order to provide you with a high quality and affordable solution.

Learning more about how our labeling solutions and innovative labeling techniques increase sales. Download The Complete Guide to Innovative Labeling Techniques.

Connect with us on social media!