Check out this economic report feature from Label & Narrow Web, written by Greg Hrinya on 07/13/2020:

Mid-Year Economic Report

Label converters and suppliers navigate the challenges and opportunities presented by COVID-19

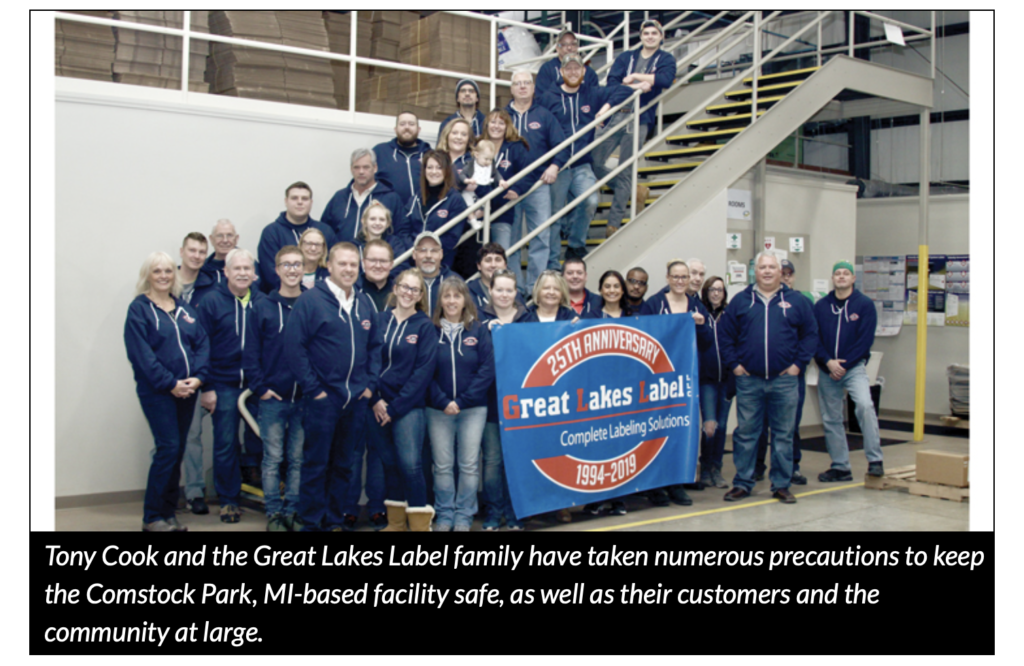

Great Lakes Label, a converter based in Comstock Park, MI, has excelled during the pandemic, and the principles of Lean Manufacturing and forward-thinking have played a key role.

Tony Cook, CEO of Great Lakes Label, established a business plan seven years ago that laid out requirements for which end uses to target. “Years ago, I felt like I had always been too heavy in the wrong industry at the wrong time,” explains Cook. “So, we really didn’t want any one industry – not just customer but industry itself – to be more than 20% of our portfolio, and then no one customer to be any more than 20% within that industry segment. This actually paid off pretty well during this pandemic because we would’ve been in a very difficult situation if we were solely in one field like automotive.”

Great Lakes Label added people and equipment during COVID-19. As other label companies laid off employees during the economic downturn, Cook brought some of those employees to Great Lakes Label to help with the spike in business. He also added a KTI turret rewind system to help streamline operations and increase throughput. Internal changes included a remapping of the company’s production floor to better adhere to social distancing mandates.

“Everything we do, we look at how can we do it more efficiently,” says Cook. “We reorganized the production floor because the rewinding was too close, and that required a sizeable investment. We made changes with lighting and replumbing all the air, plus moving a lot of heavy equipment around.”

As part of Lean Manufacturing, Great Lakes Label undertook a pre-qualification plan for all of its customers’ materials. The company pre-qualifies a second material supplier, and changes in the supply chain necessitated those procedures.

“We had to enact those supply chains because we did have quite a bit of disruption,” he explains. “Some mills handled the rush better than others. If we hadn’t done the pre-testing – which can take months to do – we would’ve been in trouble with some of our suppliers. By the time we would have gotten the supply, we couldn’t have run enough volume to ship nationally for all our customers. We had to use a second supplier probably a dozen times through the first eight weeks. Some of the raw material suppliers have actually lost pieces of business with us for good because we moved the jobs and had to recalibrate printers across the country for people, and they don’t want to go through that again.”

Great Lakes Label has picked up new business at existing accounts, where these accounts had multiple suppliers unable to meet demand. “Other suppliers couldn’t deliver because they were pushed out by their supply chain. And they weren’t small pushes either, they were 3-4 weeks,” states Cook. “It was happening every week, where it would be moved back by another week, which made it hard to plan for. This would go on 3-4 weeks in a row, and we’re used to waiting days for material, not weeks.”

Certain industries have remained slow, though. While food and grocery, personal care and hygiene, hand sanitizers, etc. have buoyed the label industry, others have reached a crawl. “We’re starting to see some orders from appliance manufacturers, office furniture manufactures and automakers, but it took 75-90 days of not ordering anything,” notes Cook. “And the orders that are coming in don’t reflect a pent-up demand, they’re very small orders that are starting to trickle in.”

Despite fluctuations in business, Cook has not become shy about pressing forward and making calculated business decisions. “For me, I’m not as reluctant to invest, but I’m going to invest in things that are going to reduce costs in the long run,” he says. “I plan for the worst with the economy, even though my gut tells me it’s going to come right back. What I’ve learned is that planning doesn’t mean cutting back everything so far that you can’t function properly, because you’ll live there forever. Right now, my mode is to double down on my sales efforts, including costs, and double down on technology investments, like the new turret winding investment, and that will drive costs down.

“I’ve tried different reactions to catastrophic events, and the reaction to go full throttle and try to grow during the time everybody else is hunkering down and trying to stay alive leads to a lot better end result. It sounds counterintuitive, because you feel like you should save every penny, but it’s not necessarily what I would do. I think you’ve got to take a chance, but it’s got to be calculated.”

#IndustryNews

See our work and labels here!

Connect with us on social media!

Facebook | Instagram | Twitter | Website

~Contact us today to get your FREE label quote~

616-647-9880 | [email protected]